Industrial IoT–Based Production Monitoring System for Injection Molding Machines

Low-cost real-time production and machine monitoring system for legacy injection molding machines.

Overview

Anwar Group is a leading building materials manufacturer in Bangladesh, operating large-scale factories that rely heavily on legacy injection molding machines. These machines lack built-in digital interfaces, making real-time production tracking and monitoring extremely challenging.

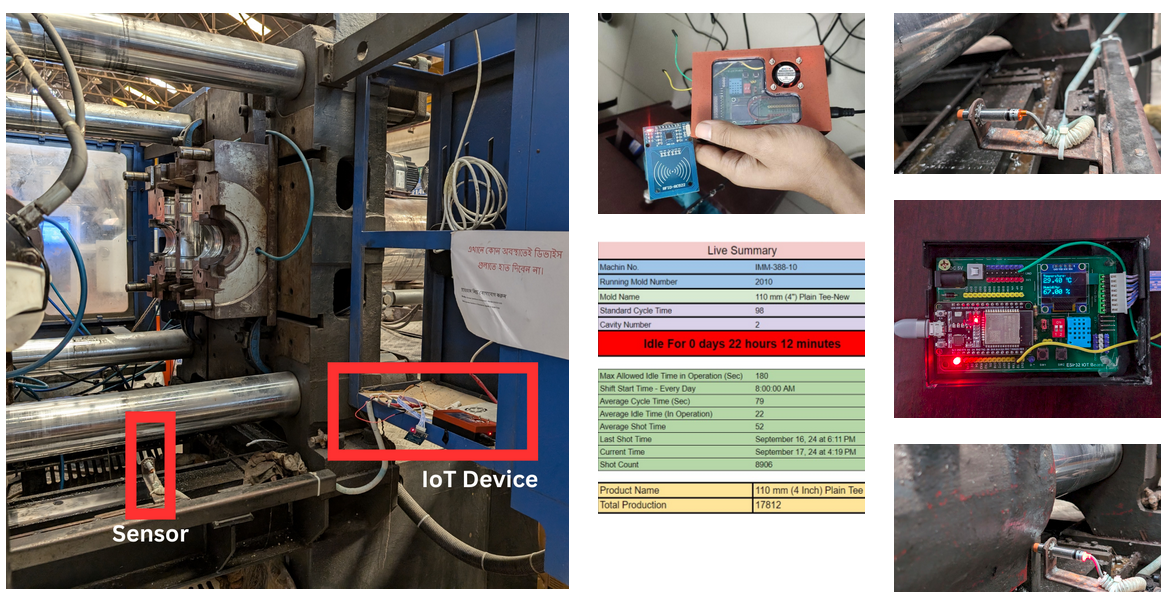

In this project, I designed and implemented a low-cost Industrial IoT solution that enables real-time production monitoring, machine status tracking, and operator identification for injection molding machines without modifying their core hardware.

The deployed system significantly improved production visibility, reduced downtime, and contributed to increased manufacturing efficiency.

Objective

- Enable real-time production monitoring for legacy injection molding machines

- Minimize cost while maintaining industrial reliability

- Track machine utilization, idle time, and production counts

- Identify operators and shifts using RFID-based authentication

My Role

Lead System Designer & Developer

I was the primary contributor responsible for:

- Overall system architecture and hardware–software integration

- Embedded firmware development and sensor interfacing

- Mechanical enclosure design and 3D printing

- End-to-end deployment and factory testing

System Design

The system combines embedded electronics, sensing, and cloud-based visualization:

- ESP32 as the central microcontroller with Wi-Fi connectivity

- Proximity sensors for shot detection and cycle counting

- RFID modules for operator identification and shift logging

- Custom mechanical housing designed and fabricated using 3D printing

- Real-time data transmission to a monitoring dashboard

Key Contributions

- Designed a non-intrusive sensing mechanism compatible with old machines

- Implemented real-time cycle and idle-time detection

- Built a live production summary dashboard (shot count, idle time, uptime)

- Delivered a scalable and cost-effective solution suitable for developing-country factories

Impact

- Enabled digital monitoring for machines previously considered “non-upgradable”

- Reduced manual logging and operator dependency

- Improved production efficiency and operational decision-making

- Demonstrated feasibility of Industry 4.0 solutions in legacy manufacturing environments

Media